Sparse seismic

CCS/CCUS monitoring

—

Times cheaper than conventional solutions

%

less CO2 emissions

%

less airgun emissions

Times faster

4 key advantages

—

Cost effective

Cost effective

Non invasive solution

Non invasive solution

Dynamic detection information away from wells

Dynamic detection information away from wells

Minimal environmental impact

Minimal environmental impact

Environmental and

operational gains

(example based on offshore acquisition)

—

Full 4D

(streamer baseline)

(for 3 monitors)

Obstruction area

370 km2

12 km2

Duration

33 days

83% shorter

CO2 emitted

4.500 tons

Gain of 91% of CO2 emission

Airgun size

2.040 Cui

600 Cui

Number of shots

60.000

3.780

98% less energy sent to water

The insurance to get the data you need, where you need it, when you need it.

our Solution

—

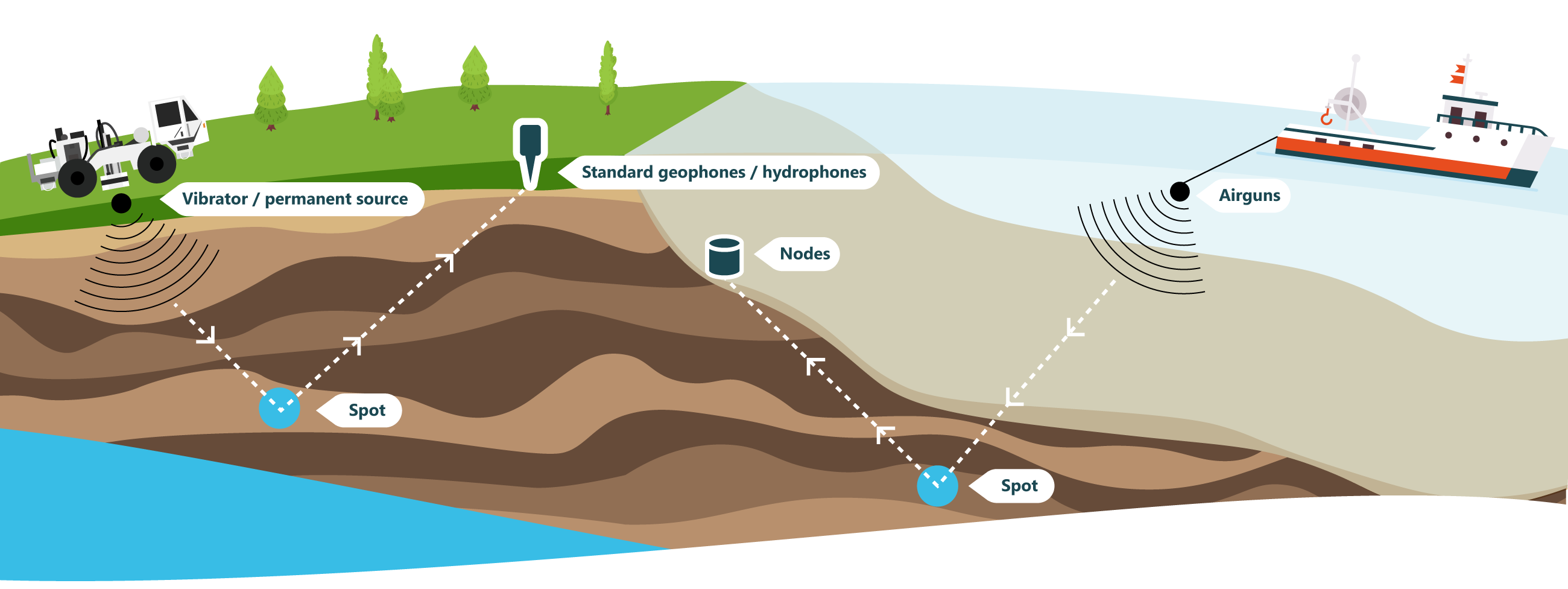

Operationally speaking, SpotLight’s disruption is to use only one seismic source and one receiver to detect a subsurface change in a given spot (pressure, fluid substitution, temperature, constraints…).

In a nutshell, SpotLight provides reservoir/production engineers with a dynamic detection of subsurface changes on strategic subsurface areas (spots) using seismic measurement (without any limitations regarding distance from wells). SpotLight’s innovation relies on the survey design and data processing, so that the acquisition is easy and requires standard equipment.

Spot Detection

Workflow

—

Consultancy for MMV

2-6months

Building a predictive maintenance MMV plan for CCS/CCUS. Integrate this plan with other MMV technologies.

Support cost & environmental footprint estimates

This consultancy phase includes the setup phase.

Setup phase

included in consultancy

Gathering existing data (GIS, 2D/3D data, horizons, PEM…) into an harmonized data base, to enable our big data analysis.

This step can include a feasibility study made of Petro-Elastic Modeling.

Done only one time per field

SpotAcquisition

Days

Installation & equipment

every 2-3 months

OUTSOURCED BY SPOTLIGHT

Done with local provider, using standard equipment, with acquisition parameter & operational model recommended by SpotLight. A data QC software is provided to the acquisition partner.

SpotMonitoring

Days

Every 2-3 months after acquisition:

Integration of newly acquired data

Patented signal/radar processing

Detection of CO2 presence (or not)

Predictive maintenance

Life of Field

Predictive maintenance is monitoring the models & the identified risk to make sure everything is happening according to plan.

With frequent & focused seismic detections we can send to our clients early warnings that are priceless to take ontime better and smarter decisions.

The SpotDetection is a dynamic monitoring tool that enables subsurface predictive maintenance

Use cases

—

✔ Alternative to an observation well

✔ Connectivity

✔ Heterogeneity

✔ Swept volumes

✔ Flood front tracking

✔ Flood direction and velocity

✔ Pathways

✔ Steam chamber evaluation

✔ Caprock integrity

✔ Conformance optimisation

✔ Pollution

Follow us on

Supported by

![]()